Facilities & Equipment

Table of contents

- General Lab Equipment

- Aggregate Equipment

- Asphalt Cement (Binder) Equipment

- General Hot-Mix Asphalt (HMA) Equipment

- Hot-Mix Asphalt (HMA) Property & Performance Testing Equipment

Balances

Features & Benefits

Accurately measures and records masses of aggregates, asphalt binder, bituminous asphalt mixes, as well as many other materials

Despatch LAC Series Ovens

Features & Benefits

- Heats asphalt and aggregate to proper mixing temperatures for the preparation of bituminous laboratory specimens.

- Conditions and ages asphaltic mixtures

- Dries aggregate material

InstroTek Water Bath

Features & Benefits

Performs bulk specific gravity measurements of compacted HMA.

Wet Core Saw

Features & Benefits

Cuts various HMA specimens to specific heights and shapes.

Core Drill

Features & Benefits

Cores HMA specimens in the lab and the field.

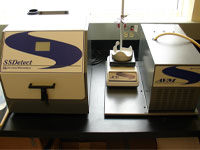

Barnstead Thermolyne SSDetect

Features & Benefits

This device is a dry-to-wet specific gravity test as opposed to AASHTO T 84 which is a wet-to-dry test.

Determines the specific gravity of fine aggregates using a laser to detect when the sample reaches a Saturated Surface Dry (SSD) state.

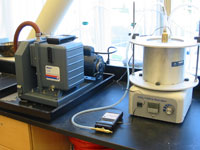

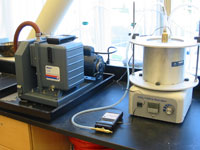

Gilson Vibro-Deairator with Welch 1405 DuoSeal Vacuum Pump

Features & Benefits

Determines the maximum theoretical specific gravity of asphalt mixes by extracting all of the air bubbles within the pore spaces between the material's particles that are submersed in water.

Rainhart Company Laboratory Sifter and U.S.A. Standard Testing Sieves

Features & Benefits

- Separates particles of various sizes.

- Develops particle distribution curves.

.jpg)

TA Instruments AR2000 Dynamic Shear Rheometer (DSR)

Features & Benefits

Determines the dynamic shear modulus and phase angle of asphalt binder when tested in dynamic shear.

.jpg)

Prentex Pressure Aging Vessel (PAV)

Features & Benefits

Ages (oxidizes) asphalt binders by means of pressurized air and elevated temperature.

.jpg)

Despatch Rolling Thin Film Oven (RTFO)

Features & Benefits

Measures the effect of heat and air on a moving film of asphalt binder.

Brookfield Thermosel Digital Rheometer

Measures fluid parameters of shear stress and viscosity at given shear rates of asphalt binders

Instron Model 5525 AsphaltPro Direct Tension Testing System

Features & Benefits

- Tests specimens of asphalt binder material to study the behavior of the material at low temperatures

- Applies a direct tension test for the study of the stress-strain characteristics of the binder test material

Thermolyne NCAT Asphalt Content Tester Series 1087

Features & Benefits

- Determines the asphalt content of a sample by loss on ignition.

- Software identifies the endpoint of ignition and indicates the completion of the test

- Applies a direct tension test for the study of the stress-strain characteristics of the binder test material

Pine Instrument Company Gyratory Compactor

Features & Benefits

Produces 6" diameter asphalt mix specimens to densities achieved under actual pavement climate and loading conditions. Device is portable.

ELE Marshall Compactor

Features & Benefits

Produces 4" asphalt mix specimens based on a pre-determined number of blows.

Gilson Vibro-Deairator with Welch 1405 DuoSeal Vacuum Pump

Features & Benefits

Determines the maximum theoretical specific gravity of asphalt mixes by extracting all of the air bubbles within the pore spaces between the material's particles that are submersed in water.

Rotavapor Extraction and Recovery Device

Features & Benefits

- Extracts and recovers asphalt binder from asphalt mixtures [both hot-mix asphalt (HMA) and reclaimed asphalt pavement (RAP)].

- Assists in determining the quantity of asphalt binder in HMA or RAP.

- The recovered aggregate can be used to determine the particle size distribution curve.

InstroTek Corelok

Features & Benefits

Vacuum chamber that is used to determine the bulk specific gravity of bituminous asphalt specimens.

Lindberg Blue Constant Temperature Waterbaths

Features & Benefits

Waterbaths are capable of automatically controlling temperature within close ranges. It brings materials to desired constant temperatures for various testing purposes.

.jpg)

IPC Simple Performance Test Device (SPT)

Features & Benefits

Closed loop servo-hydraulic test machine, designed based on the requirements of NCHRP Project 9-29 "Simple Performance Tester for Superpave Mix Design."

Testing results from device are used to evaluate the resistance of Hot Mix Asphalt (HMA) to permanent deformation and fatigue cracking. The models used to calculate and quantify the testing result were developed in NCHRP 9-19 "Superpave Support and Performance Models Management." Three test applications are completed with this device:

Flow Time Test

Flow Number Test

Dynamic Modulus Test (E*): The test is of great interest to many local, state and federal agencies as it will be a design requirement of the new AASHTO pavement design guide.

MTS with Environmental Chamber

Features & Benefits

Closed loop servo hydraulic Universal Testing Machine (UTM) with a bottom mounted actuator is used for a variety of HMA testing procedures including:

Indirect Tensile Strength

Resilient Modulus

Creep Compliance

Many custom testing procedures can be designed and completed with this device since the software and control features are fully programmable. The attached environmental chamber provides flexibility to test at a wide variety of temperatures from -20°C to 60°C.

.jpg)

Model Mobil Load Simulator (MMLS3)

Features & Benefits

The MMLS3 is an accelerated pavement testing device (shown on the right) that applies realistic trafficking to the pavement. The load is scaled but tire pressures are the same level as in full scale trucks. The device can be used to directly explore the performance of the upper 125 mm of asphalt pavements in the laboratory and in the field. Scaled down models of the pavement can also be tested to investigate the performance of the full pavement structure.

The MMLS3 can characterize an asphalt mix and predict the performance using the following variables:

Load frequency

Temperature

Lateral wander of the load

Aging of material.

The loading from the MMLS is uni-directional and the speed can be adjusted. Laboratory testing can be completed on gyratory specimens, field cores, or slabs. Numerous research projects have been conducted to validate the MMLS3 results to real trafficking data at the NCAT test track and the WesTrack facility. The MMLS3 system is compromised of five main components:

MMLS3 Loading Unit

Slab Compactor

Heating -Cooling Unit

Wet Pavement Heater

Profilimeter.

The slab compactor

The slab compactor (shown on the left) has a vibratory drum roller for constructing slabs in the laboratory. These slabs can be constructed up to 3 feet wide by 9 feet long. Once construction is completed the MMLS3 load unit can be placed on top of the slab and tested.

The Heating-Cooling Unit and Wet Pavement Heater (not shown) are used to environmentally condition the prospective test specimen whether its a gyratory specimen, field core, or slab. These are used to simulate the field conditions of the pavement in the laboratory. Similarly these units can be used in the field.

The Center’s Materials laboratory utilizes the MMLS3 to test the rutting and fatigue resistance of various HMA mixes. Rutting is typically performed on 9 gyratory specimens, but can be completed using slabs as well. Fatigue testing is typically completed utilizing slabs only.

The Center’s Materials Lab has also developed its own test for specialty mixtures using the MMLS3. The MMLS3 allows versatility in laboratory experimental testing and setup.

.jpg)

Pavement Technology Inc. Asphalt Pavement Analyzer (APA)

Features & Benefits

The APA is a multifunction loaded wheel tester used for evaluating permanent deformation (rutting), fatigue cracking, and moisture susceptibility in asphalt mixtures.

This device simulates field conditions by applying a wheel load and measures the amount of permanent deformation under each wheel path. Wheel loading for this device is bi-directional and the speed is fixed. The APA is capable of testing six gyratory of field cores at one time.